One of the interesting things I observe, looking at businesses that struggle with their on time delivery, is their attention to deliverables.

Delivering on time is easier, if you have the right targets. Often I see businesses aim at something that is not the finish line. In some cases they focus on the wrong finish line. Let me look at both scenarios.

Scenario 1 – client projects and production output

When delivering to a clear client specification you have to wonder how this could go wrong… apart from resourcing, technical challenges, breakdowns and anything else of course!

But, I often see delivery teams focusing on ‘nuts and bolts’ and not the final outcome. For example, a factory that thinks their products are complete when the last piece is welded but downplays the surface treatments, assembly, final inspection and packing activities.

Or, the project team that avoids front loading their schedules because they know how the software needs to written but don’t consciously consider all of the testing, documentation and final tweaks.

Even with a clear project timeline, or a production schedule, if the focus of the team isn’t on clear milestones to achieve the whole thing then progress can slip. And, if the focus isn’t on the true deliverables then what the team think is the finish line isn’t. The real finish line might be another sprint away, adding extra pressure to the deadline.

Scenario 2 – Wrong finish line altogether

Whilst the first scenario looks at the focus we place on the finish line, what if you are running the wrong race?

I had a great conversation the other week with a large online retailer regarding my order. The wrong product arrived but according to their system the delivery had been successful. I imagine that someone in their warehouse put my packing label on the wrong product… It took me another go (after their full refund and being gifted something I don’t want or need) to place the order and receive the original item.

How many times have you seen this? The wrong specification marked on paperwork. An unclear project deliverable being left unclarified until it is too late. A contract item not being understood by the delivery team and then being questioned at the end of the contract.

All of these kinds of issues can be clarified at the start, which is why most businesses perform a contract review (or similar).

Some options to ponder

You may recognise one or both of the above scenarios. It is true that the little things at the end of delivery activity can really be a lot more intensive than we hope / expect. It is also true that if we don’t know exactly what we are delivering we can end up in the wrong place.

So, what can we do about this? Here are some ideas for you to play with:

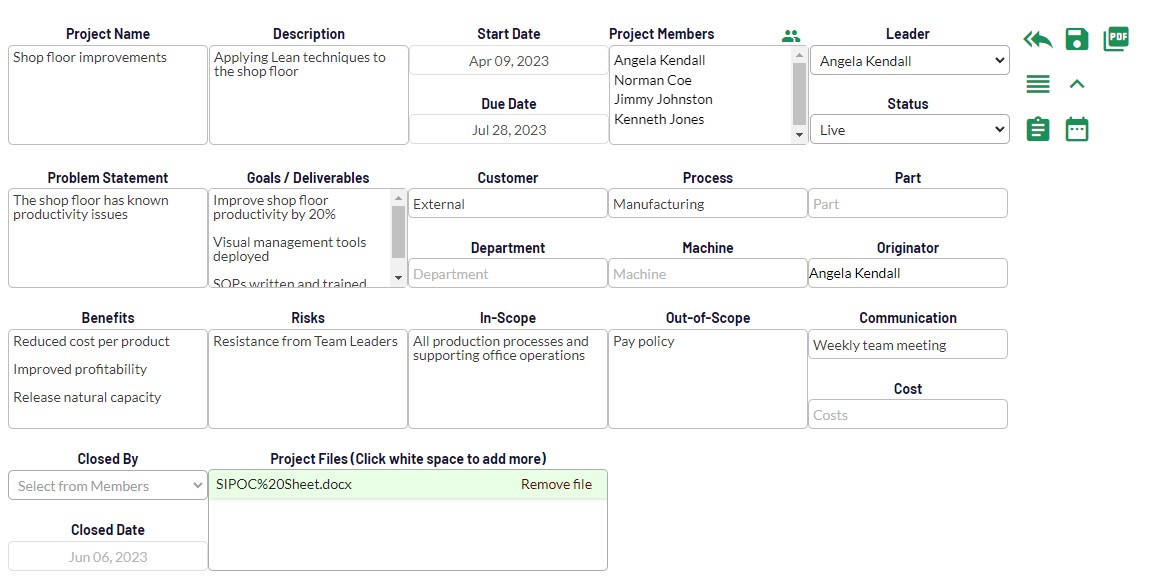

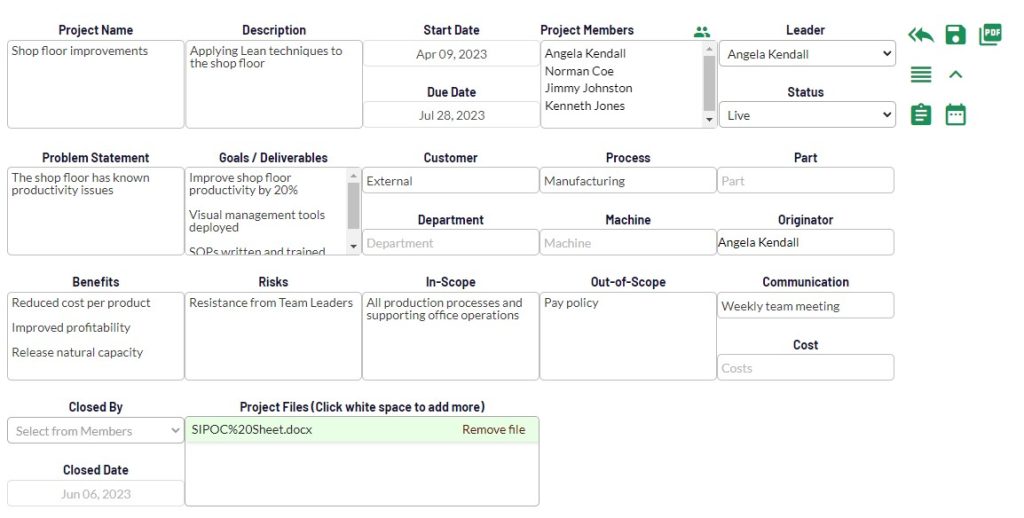

PIDs

PIDs (or, Project Initiation Documents) are a great way to clarify what you want your teams to do. If you are running internal projects these are especially useful. The formality that you experience from another organisation requesting your services is usually missing within an organisation. The time it takes to pull a full specification document, and the speed at which you want to achieve the project, possibly make this the case. But a shortened version, which is quick to complete, can be the answer.

Headings could include:

- Problem definition

- Deliverables

- Communication / reporting

- Team

- In scope / out of scope

- Benefits and risks

If you want some free software to create a PID, claim your free PDCA Complete account here.

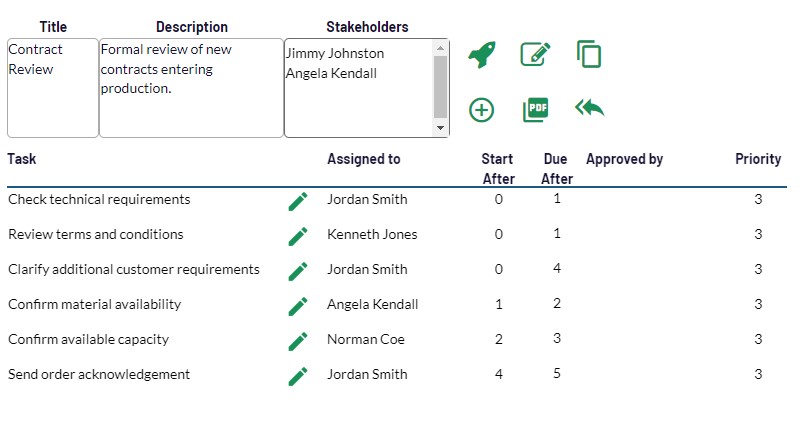

Contract Review

Creating a checklist to ensure that all deliverables are known to the project / production team is a good way to avoid either delivering the wrong thing or missing out the final few steps.

You don’t need anything complicated and the review doesn’t have to take long. A small cross functional team looking at the contract is all you need. If you use a digital system, you don’t even need to be in the same place, at the same time!

Review elements can include:

- Review of capacity

- Review of capability

- Clarification (and ownership) of each deliverable

- Supply chain considerations

- Documentation and licenses

- Confirmation of delivery dates

5W1H

The definitive go to tool for clarifying who does what is 5W1H.

The name refers to five words beginning with ‘W’ and one with ‘H’:

- Who

- What

- When

- Where

- Why

- How

‘Why’ is mostly needed if the purpose of the activity isn’t clear. Otherwise you have some specific headings to hang the detail of what you want. This is particularly useful when you are clarifying with your team what you want, when managing your internal processes.

These kinds of conversations can improve process performance, which often helps you to deliver your projects and production both more effectively and efficiently.

If you want some more ideas around this, check out my book What Does Good Look Like?

What would work for your business?

These are just a few ideas to get you thinking. How could they apply to your business to increase your on time delivery performance?

Play with the ideas and see if you can use the principles to make what you do today even better tomorrow.

Improving on time delivery performance certainly is made easier by being clear on the details at the outset.