Many businesses that I speak to with delivery challenges already measure their on time delivery. It isn’t just a hunch that they are delivering late, they know!

The problem in many of their cases is that they have a very basic view of what is late and why it is late. They aren’t effective with their information and by changing this situation, results can change quickly.

In this article I am going to share a few pointers I use with my consulting clients to improve how you measure on time delivery performance and then realise better results.

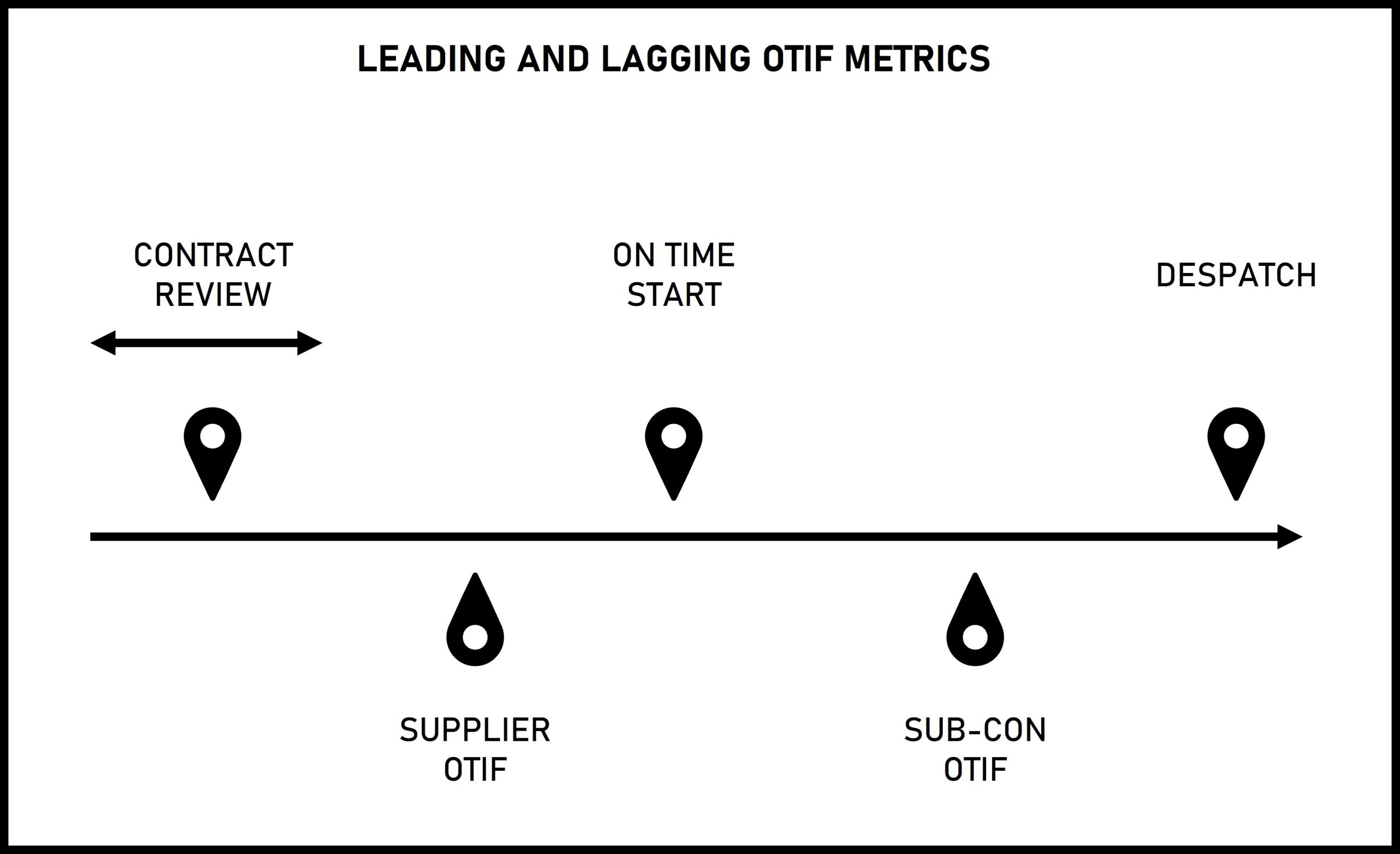

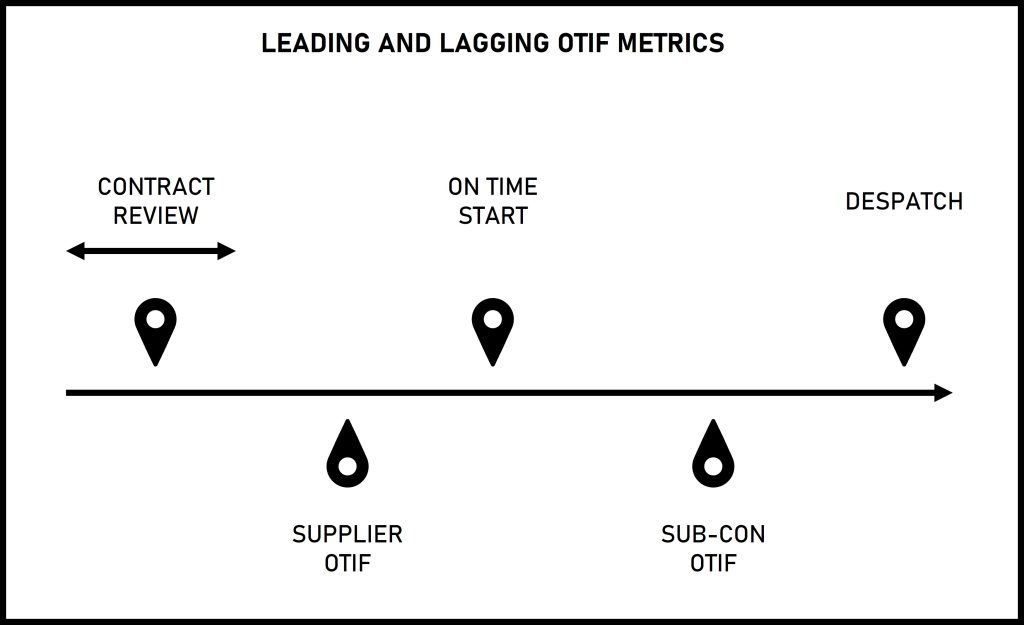

Leading and lagging indicators

The first point I want to make is the difference between leading and lagging indicators. Many businesses that take a simple view of delivery performance use only one indicator and that is often what we call a lagging indicator.

As the name suggests, lagging indicators tell you what happened. Leading indicators, provide clues about what is going to happen.

Better visibility about your production activities gives you the opportunity to change course. A few small changes can often yield better results at the end. I should also make a point here that when I refer to production activities I include things such as delivering a service, carrying out manufacturing operations, construction tasks or anything that gets you closer to what the customer order states.

Some ideas on OTIF (On Time In Full) metrics

Here is my standard ‘go to’ list of OTIF metrics to help you understand what is happening from a delivery perspective:

Contract review lead time (leading indicator)

You might call this something different in your organisation. I am referring to how fast you can review and prepare your customers order for ‘production’.

Without cutting corners, how long does it take to mobilise production within your business?

Supplier performance (leading indicator)

For many organisations, nothing happens until materials arrive. What is the performance of your suppliers? Having a low on time delivery performance coming into your business doesn’t help your final OTIF score.

On time start (leading indicator)

Do you start your production activities on time? Are you aware of the delays your teams face?

Many businesses don’t look at this factor as they are too busy trying to put fires out at the other end. Like the supplier deliveries, if you start late, finishing on time is hard.

Sub-contractor performance (leading indicator)

Monitoring the performance of your sub-contracted services is another vital element to consider. Overpromising and under delivering is common within sub-contractor supply chains.

Whilst this group are outside of your control, good working relationships make this area easier to manage.

Despatch (lagging indicator)

Finally, the result! What is the OTIF score for your business?

Don’t be soft on yourselves. Don’t fool yourself by being generous with the window you use to score your performance. Also, measure promises where you can. Giving yourself a high score because you got most of the order delivered on time isn’t the standard we want to be aiming for!

If you are tougher on yourselves than your customers, high and consistent on time delivery is possible. Changes don’t come from burying your head in the sand!

Using your Key Performance Indicator (KPI) data

Knowing your numbers is one thing, doing something with them is another.

Decision making is one of the obvious things to do with your KPIs.

What does the information tell you?

Does it guide your thinking?

If it doesn’t it might be that you are measuring the wrong things. Look for trends and it should inform your actions.

You can revise your resources and routines based on your data. It might be necessary to formalise team calendars or move people around for your processes to work effectively. See what the data says and reallocate efforts accordingly.

Working with the supply chain is logical. If your supplier or sub-contractor data tells you they’re late, look into it. There may be opportunities to improve communications or clarify requirements. If you come to a conclusion that they aren’t good partners for you, then you can hopefully move on.

The path of least effort

If you aren’t measuring OTIF effectively, across a range of measures, don’t despair. This doesn’t have to be a crusade and suck all your resources away.

Be selective. Look at the list above and see if there is something that jumps out at you and start there. If in doubt, start at the beginning and measure the first point you can. If it is OK, stop measuring it and move to the next step.

You only need to measure things that you are going to do something about. If everything is OK, you can just measure the final OTIF score. My suspicion though, once you start doing this, is that you won’t want to leave it at one measure!

Resources