Are you familiar with the on time delivery ‘hockey stick’?

If you are familiar with this phenomenon and have a problem with delivering on time, consistently, then keep reading.

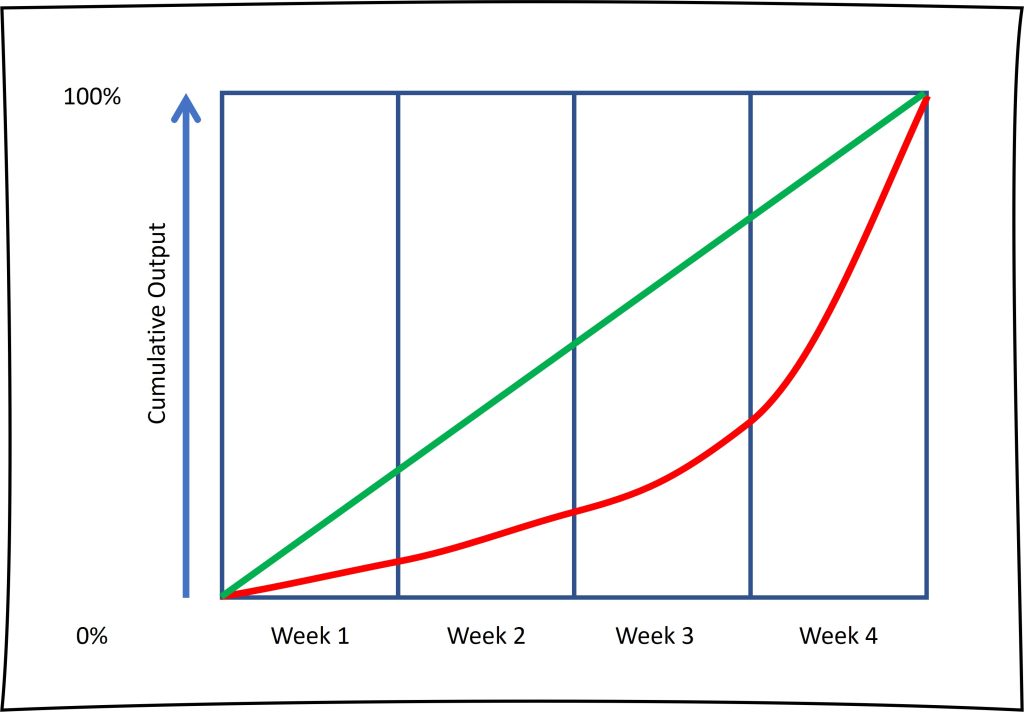

For those of you that haven’t come across this term before, it refers to the increasing levels of output experienced during the course of the month, as shown in the image below. The red line demonstrates what a lot of organisations experience, continually ramping up output, week on week, until the month end. The green line is what most organisations need to aim for.

If you squint, the red line looks a little like an ice hockey stick, hence the name!

Are you under pressure to deliver?

Living with the hockey stick puts you and your team under pressure. Unnecessary pressure at times.

Who feels the pressure?

- Suppliers (when you’ve forgotten to order materials early enough).

- Sub-contractors (as they try to beat your unrealistic deadlines, due to a delayed start).

- Your team (as the frantic action cumulates towards month end).

- Your customers (when your shipments are at risk and their customers complain to them).

- You (as you get asked to explain progress, again).

Smooth and steady is the way forward

Deciding to operate in a different way is the first step.

But, what is the second step?

Smoothing out the delivery profile is the right approach, and knowing what that means in numeric terms.

If you ship 100 units in a month, let’s say, you don’t want to be shipping 80 of them in the last week. 25 per week, like a steady drumbeat, is a better way to manage the output.

Once you know your number you have a standard. Something to work on with the team.

What gets measured…

… gets managed. Start talking to your team about this number and holding yourself accountable.

Figure out what changes you need to make in order to move from the lumpy month end to a regular output. This requires you to be systematic about the way your team runs your operations.

Steady, controlled, routine. I imagine you can visualise what changes you will need to make with your team at first.

This is cause and effect. Shifting your focus away from month end, to weekly, or daily output, is how you get there.

Let me give you a few ideas to think about:

- Can you improve your staff handovers, so tasks aren’t forgotten about? Can checklists be used?

- Can you move any of your supporting tasks to a daily routine? Purchasing, engineering sign off, concessions etc…

- What delays do you have in your decision making process? Can you focus on eliminating these?

- Is progress visible? Can it be made clear to the whole team?

- What stops your processes from starting on time? Information, capacity, focus?

- Are the orders too lumpy? Can shipments be broken down?

Is it worth the effort?

It isn’t easy to achieve a smoother output but in most cases it isn’t hard either. Persistence can count for a lot!

Changing the way that you measure your output is key. Aiming for regular output means that you focus differently on things like:

- material procurement

- scheduling

- deliveries to sub-contractors

- communications with your customers

- communications with your colleagues

- prioritising maintenance and repairs

- visible metrics

- holding each other accountable

But what are the potential results?

- Less stress and strain for the team.

- Happier customers and potentially more orders to fulfil (customers like smart and reliable suppliers).

It is worth the effort, smoothing out your weekly output.

Easier OTIF is around the corner

On Time In Full is easier to achieve when you have a systematic approach to follow. Ideally a system that you have created.

Instead of on time delivery being guesswork and crossed fingers, you run the routine and measure the process.

If you currently experience the hockey stick effect then I urge you to look at how you manage and trigger your processes. Define a standard output for each week (or better, each day) and see how you get on. Every time your deliveries fall over, ask ‘why?’ and challenge yourself to fix the problem you discover.

Within a few months you should be operating in a different way with far better results.

Snap the hockey stick and throw it away! You don’t need it.