If you’re reading this you are most likely looking for ways to improve your OTIF performance. OTIF stands for On Time In Full, if you aren’t sure. I like the OTIF approach as it is absolute. There isn’t any fudging the numbers. You either kept the promises made to your customers, or you didn’t!

You can’t improve your scores for a half kept promise.

Keeping promises around delivery is at the heart of OTIF. So, in this article I am going to look at how standards affect this. We have standards all around our businesses, but are they a complete set?

By the end of this article I am hopeful that you see standards a little different. And, if I have done my job right, you’ll have some ideas to improve your business.

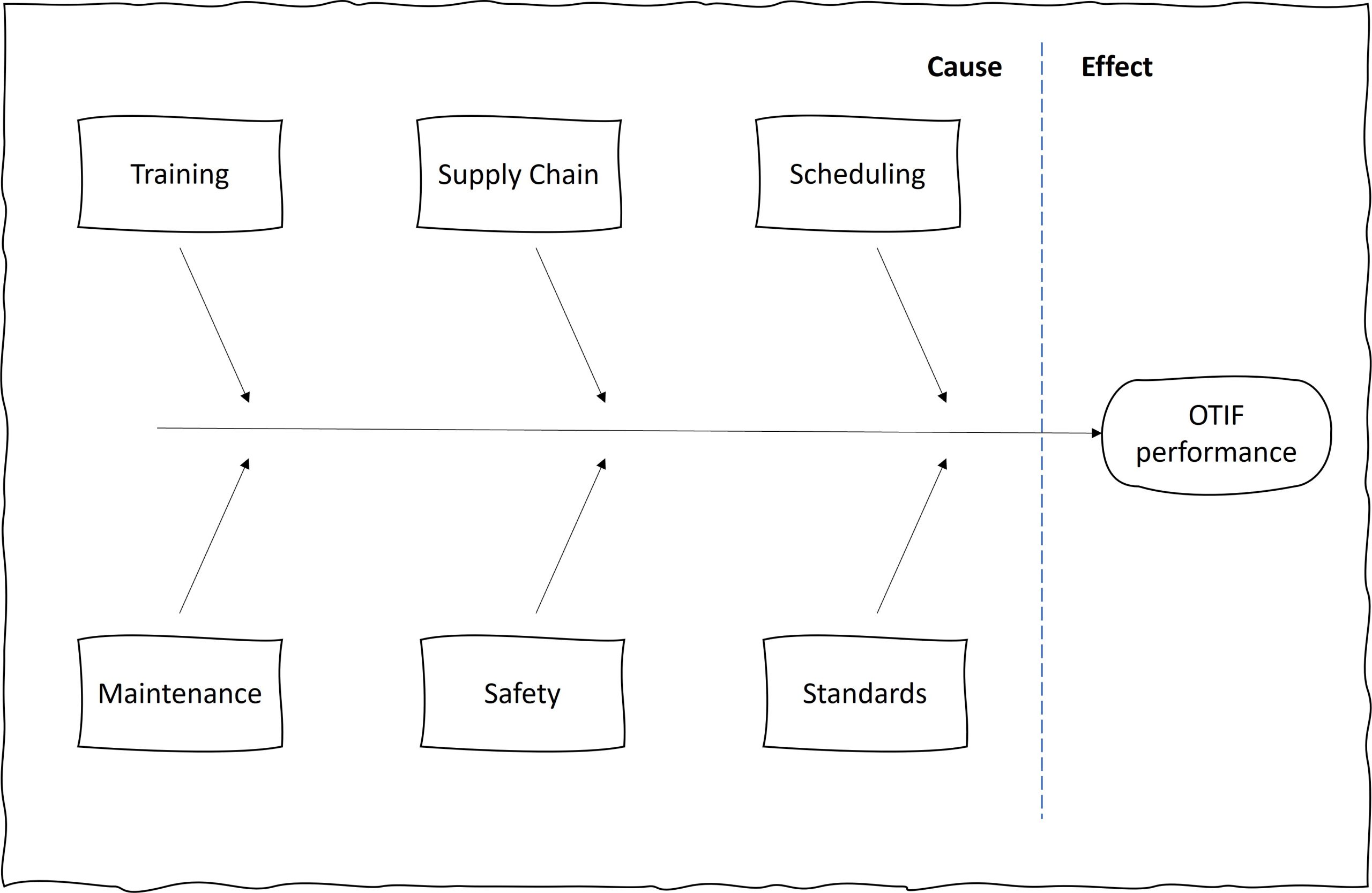

Using cause and effect to set standards

The logic behind this article is based on ’cause and effect’. You do something and you get a result.

In business we have these relationships everywhere. Often we don’t spot them until a disaster has happened. The uninitiated will complain about crises being ‘out of the blue’. The experienced person will realise that there was a chain of events beforehand.

What do causes look like?

The reason many businesses get caught out is because they don’t recognise the causes. They’re usually small things that happen without fanfare.

Many people use the fishbone approach to analyse failures. Few people use the same approach to design success. If you look at this from an OTIF perspective, what can cause consistently high levels?

- A safe working environment

- Well maintained machines

- Trained and flexible staff

- On time supply of raw materials and components

- Clear instructions and guidance

- Policies that make sense and are easy to follow

- Effective scheduling

- Productive working practices

- Making decisions on time

I’m sure that you can think of more items to add.

Behind each of the above items there will be more factors and tasks. If I take the clear instructions item, tasks could be:

- Someone qualified reviews the instructions on a regular basis.

- Instructions are up to date.

- They are in a format that is easy to understand.

- The documents are accessible.

- Training synchronises with the instructions.

- Document numbering is logical and their organisation is good.

Again, I am sure that you can think of more. If you repeat this process you should arrive at some true causes (often policy making). These are tasks that are in your control to do something about.

And, if you undertake these tasks, then you should be on the right tracks to generate the effects you want (high OTIF).

5W1H

A fantastic tool to help you get the most out of this exercise is this trusted tool. I think it was ripped off from a poem, but engineers have squished a series of prompts into this list:

- Who

- What

- When

- Where

- Why

- How

(Five things beginning with W and one with H, get the name now?)

The list of causes is the ‘what’ element, ideally as a clear deliverable. The ‘why’ is the effect you want to achieve.

If you work down the rest of the list you have a pretty good list of prompts to define the rest of the causal task:

- Who is going to be responsible for this task?

- When are they going to perform it?

- How do they complete the task?

- Where will they carry out the activity?

If you can answer these questions, for all the causes, you will have a comprehensive set of standards.

Build your routines

Depending on the ‘when’ answers to your exercise, you may have already defined a routine. Or, at least, the outline to it.

To get the most out of these standards you’ll need to link them to something. For most organisations this will mean that they’ll:

- tie into existing processes, as a trigger.

- become a checklist to use mid-process.

- end up being a formal routine in their own right.

If you think about these points, a routine will emerge.

Go for full coverage

Do not underestimate the small things on the list you have created!

Often the smaller items are the ones that get missed. Miss them today and you likely won’t notice. Miss them for enough days / weeks / months and you may end up with a serious headache!

Remember cause and effect? The link between the two may not be obvious until you do some digging (or an exercise like the one above).

I meet countless organisations who try to tell me about their priorities. They tell about how busy they are. Of course they are! They are in crisis and have to do the same job twice. When you do some digging (aka root cause analysis) you often find these small tasks…

Watch, learn and refine

At the heart of the continuous improvement approach is the PDCA cycle. PDCA stands for Plan Do Check Act.

I would urge you to use this approach to improve and refine what you do here. Setting standards can drive up OTIF performance, if you are doing it consciously.

If you’d like some free software to help you manage and monitor this activity, then check out PDCA Complete.

Take the improvements you are making and ask if they are hitting the right spot. If they aren’t, use your observations to tweak the approach and try again.

Measure the results and keep going. It is this simple.

High OTIF levels shouldn’t happen by chance. If you take the time today to look at what you are doing you can make a difference. Figure out the cause and effect relationships in your business. Look at the small things that you are missing and fix them into your daily schedule.

Consistently high OTIF comes when you live and breathe this approach!