Over time, standards tends to degrade. Staff both accidentally and purposefully change what becomes the norm within a business. The same goes for discipline (as in, doing what is agreed without deviation).

Not addressing these minor changes can lead to performance issues. This can directly affect on time delivery performance and the customer experience.

Upgrading and restoring standards and discipline needn’t be a big job either. Restoring them is just as simple as how they slipped way in the first place.

Where’s the routine?

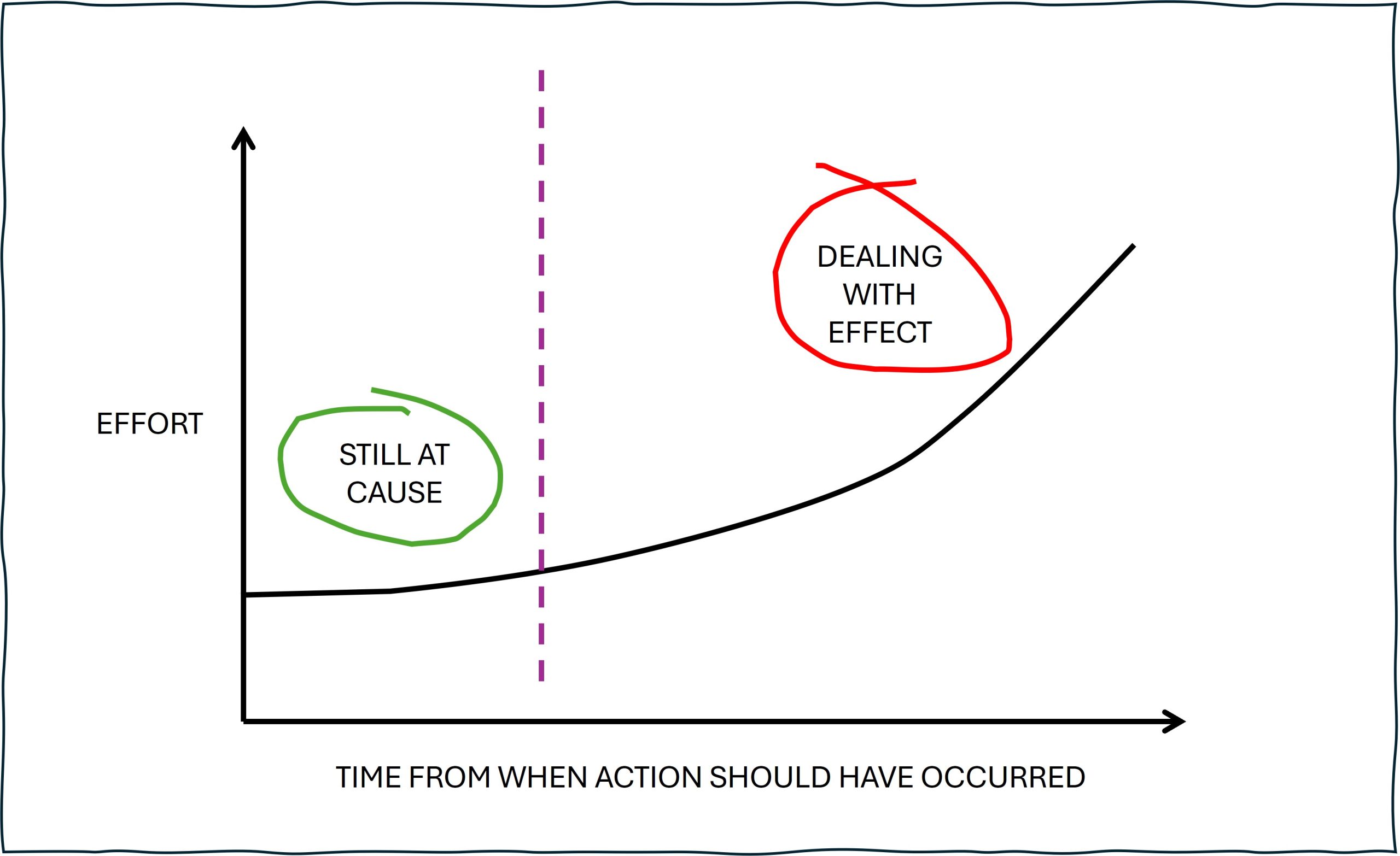

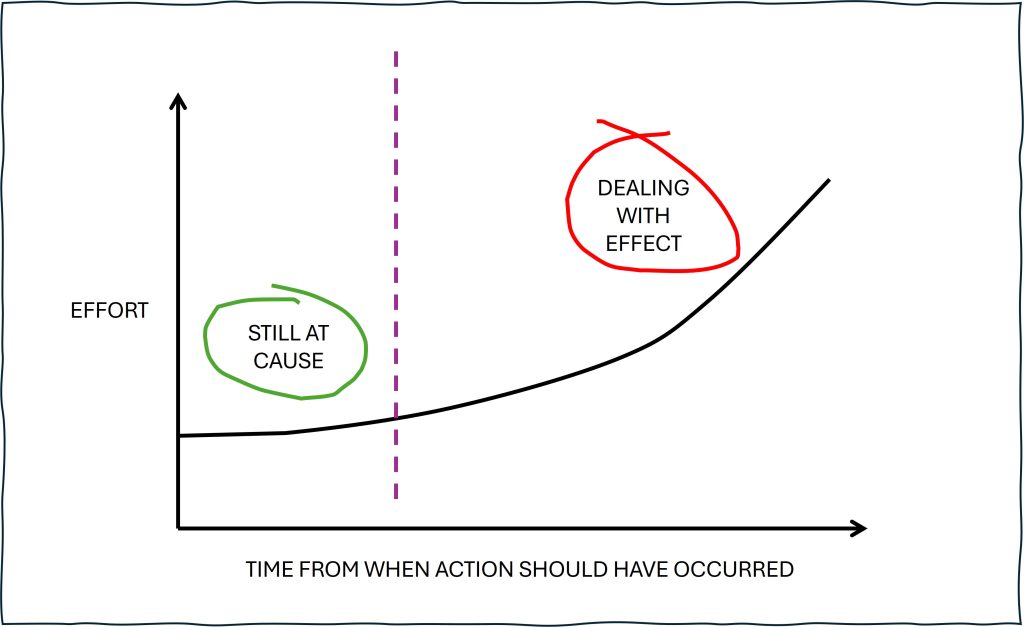

When there is a lack of a defined routine in the business, smaller tasks have the opportunity to drop off our radars undetected. This may seem innoxious but small problems can build over time.

Weekly reporting might not cause a problem if it misses a week. Cancelling the team meeting won’t cause a problem if it is just one day. The tidying up of the server won’t turn any heads if it misses this month’s deadline.

But, one skipped event, compounded by more missing activity could lead you down a path you don’t want to venture. Decisions stop flowing. Team members miss out on important discussions. Files become lost on servers. I’m sure you get the idea. The problems that follow can stop you from delivering on time and the effort required to get back on track is a lot more than carrying out the routine task in the first place.

Defining a routine that helps the business to perform is a simple task for the management team to undertake. Knowing what needs to be done when, so that you get the results that you need, is what you do here. Defining a routine also helps to clear out old tasks that have no purpose that are still being carried out (the opposite of our problem here!).

Defining all the planning steps

If you keep your business processes in your head, without writing them down anywhere else, you run the risk of further degradation.

What you recall being the eight steps of your process can change over time. I see this all the time. The recollection of staff can’t always be relied upon. Work pressures can alter work practices (unintentionally) and from there new memories can be formed. For example, you find yourself stretched due to work demands and you miss a step in the process by accident. If there is no immediate repercussion, the step might not get reintroduced.

This is a similar situation to the example of the routine getting adjusted unconsciously. However, if you define all of your process steps formally (as in a Standard Operating Procedure (SOP), or a management handbook) then you have less chance of forgetting. Documenting processes can be straightforward. A simple flowchart or a document with a handful of bullet points can push you in the right direction.

Skipping steps, that are there for a reason, can send you into crisis if you don’t keep an eye on this. Crises take up too much energy, focus and goodwill if this becomes your normal way of working. Apart from steering you away from great customer relationships and consistently high on time delivery performance, it can affect staff morale in the longer term.

Say ‘no’ to worse

When you start accepting less than you know you should, in terms of standards, you tread a slippery slope. If you know something isn’t good enough / right, you need to nip it in the bud.

Degrading standards can be a slow and stealthy process. You know how this goes. Everyone is busy, a decision gets made to do a little less than what has been previously agreed. There’s no immediate disaster, so the new standard establishes.

To avoid this situation in your business, there are two key actions you can take:

- Set, or clarify, the standards you want in your business.

- Keep an eye out for what you want to see and call out bad practice when you see it.

It doesn’t have to be any harder than this. Consistency is key to achieving high levels of on time delivery performance and you have an opportunity to lead here.

Keeping the standards in check

Hopefully you have seen a couple of points in this article that you can use in your business.

Whether this is defining standards, capturing knowledge in SOPs or management observation, I hope that you come up with some options to improve the level of standards and discipline your experience. This should directly translate into improve delivery performance.

If you are looking for some ideas on making better use of SOPs, or developing effective routines for your business, then check out these two books:

All the best,

Giles