We all want a high, consistent, OTIF (On Time In Full) performance. Standards are a key part of that experience. Setting them, maintaining them and raising them.

In this article I am going to explore what happens when you let them deteriorate. Even when this happens by accident, it doesn’t help your cause.

OTIF is a chain of events

If you consider your order fulfilment process, OTIF is a literal chain of events. From how you process your sales orders, to planning your delivery and executing your plan.

The chain involves many people. Each link in the chain needs to have high standards. The impact of one area degrading can produce a snowball effect. The whole system begins to underperform if you lower your standards.

Standards keep your processes in check

We document standards to keep us on the ‘straight and narrow’. Humans are subjective creatures. Standards provide the single source of truth that businesses need.

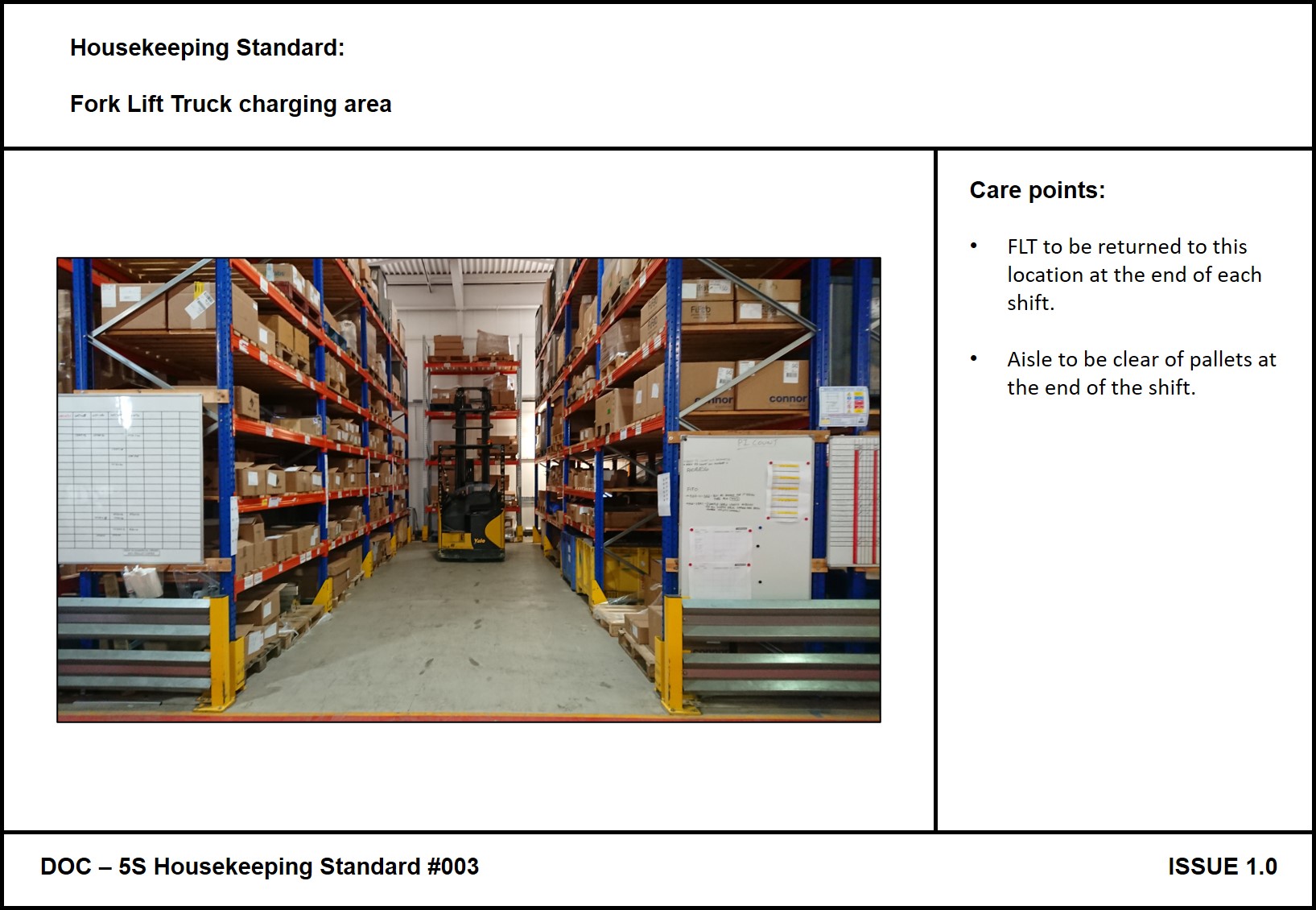

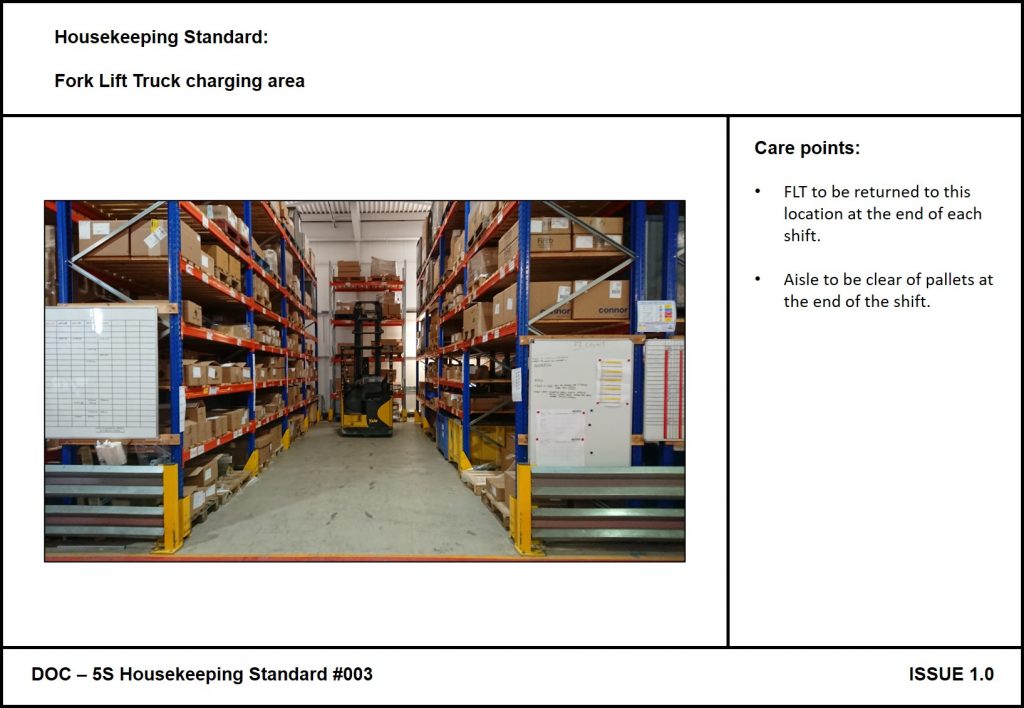

You can capture standards in a variety of ways:

- Standard Operating Procedures (SOPs)

- Visual standards

- Flowcharts

- Key Performance Indicator (KPI) targets

- Skills matrices

The key with all these approaches is that you define what good looks like and write it down.

Beware of negotiating

…this is when disciplines start to fail!

If you find yourself negotiating with yourself, that is one thing. When you have your team negotiating to drop certain practices, beware!

This negotiation can happen when you are busy, when the pressure feels too much. Dropping the occassional task can lead to other issues in the business, which I’ll come back to in a moment.

When you drop a task because it is superfluous, that’s called improvement.

When you drop a task because you have devalued it, that’s called expedience.

Let’s discuss the downside of dropping tasks when they aren’t improvement opportunities.

Small changes become big losses

The trouble with dropping small items from your working day is the impact. Rarely people stop to acknowledge the bigger picture in these cases.

In the some cases, these drops in knowledge affect performance immediately. In these cases there is an immediate reversal. Learning is quick and effective.

But, when there is no immediate effect, deterioration begins in the organisation. The rot starts.

Loss of knowledge

If staff choose to stop doing certain things, you run the risk of losing knowledge. If there is no ongoing practice there is the chance that people forget how to perform certain tasks.

When new people join the organisation they are then not told about about these tasks. The cycle continues until no one remembers what they should be doing.

Loss of habits

This stopping of performing chosen tasks diminishes your business habits. Forming habits is a hard thing to do for most of us.

If the dropping of a task is for time saving reasons, performing that task next time becomes harder. If there is no immediate impact then the cause and effect link isn’t obvious.

Not eating an apple today, doesn’t mean that you will die tomorrow. Should you eat an apple a day? You get the idea!

Degradation over time

This is where loss of knowledge and loss of habits takes us to. Our performance runs the high risk of degrading over time.

The most likely outcome is that small tasks lead to a chaotic situation later on. The small task that you skimp on can create an almighty fall for someone else. This person is usually at the back end of your business process!

Incorrectly raised purchase orders create an avalanche of purchase invoice queries.

Undocumented customer requirements lead to incomplete deliveries and customer complaints.

You remove key dimensions from drawings and wonder why products aren’t right.

You choose not to document an activity and watch ineffective training take place.

I’m sure that you get the idea. This effect is known as the ‘broken window theory’. This theory refers back to abandoned warehouse windows. If a window gets smashed but not replaced, shortly afterwards all the windows get smashed. If, you replace the smashed window the other windows stay intact. In the second case you maintain the standard and communicate this standard to others.

Please don’t underestimate the dropping of standards and the effect it can have on the wider organisation.

Reversal and OTIF improvement

So, how do we use this to raise OTIF performance?

To me, there are a clear number of actions any business can take:

- Document your processes.

- Document the standards you expect, including performance targets.

- Audit your standards on a regular basis to ensure they are in place and effective.

- Ensure your leadership team have the highest standards. They need to live and breathe them!

- Hold people accountable if they deviate from the standards. Do this immediately, don’t let the decay build up.

- Only drop tasks if they are redundant, not because of being short of time. Re-engineer difficult or time consuming tasks instead.

- Periodically raise the bar!

If you have found your team negotiating their way out of performing certain tasks, think again. Also, there might not be a negotiation, they might just stop doing the tasks altogether.

If you have realised that you need to document some more of your standards, don’t let time be the excuse. Often, carrying out the tasks saves time later on. If you have your standards documented, their disappearance is more obvious.

Sustaining high standards improves a lot of things, it definitely improves OTIF performance!