I had a good call with a business last week about improving on time delivery performance.

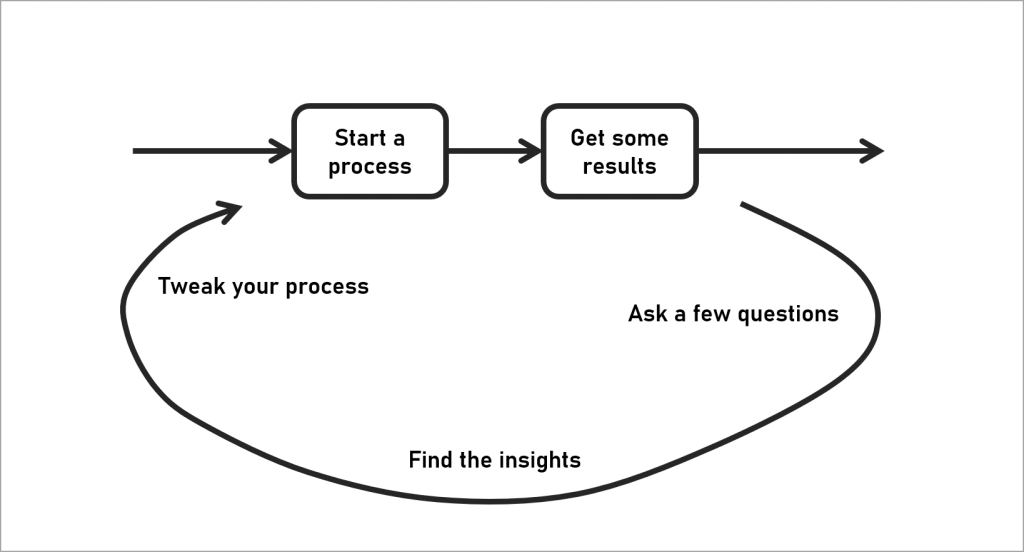

We talked about quite a few points around this topic, but one stood out to me from the conversation. It was about learning and ‘closing the loop’.

Most of us know the importance of lessons learned and PDCA (Plan – Do – Check – Act). Take the time at the end of a project to decide what went well and what didn’t. Choose what you want to do more of and what you want to do less of.

Not rocket science.

I see a lot of businesses that carry out lessons learned with their customer facing projects. If you have a formal ISO 9001 quality management system then you will know all about this. You want to get it right for your customers (so that they come back and buy another project from you) and so this is a logical thing to do.

I also see the PDCA approach get used (with varying levels of success) with continuous improvement projects. Specific projects with a clear scope to fulfil. If it is done right here then you should find future improvement projects get delivered more quickly and with better results.

However, I rarely find such good approaches just applied to general business processes. Yes, you can apply the closed loop feedback system at any point and at any time.

I feel that the challenge that most businesses struggle with is the crush of the working day. No sooner have you seen your results you are catapulted right into the next meeting / crisis / project.

Where do you find the time to carry out this review?

Firstly, I think that many of us ‘big up’ the need to carry out a formal review. Just asking yourself the questions:

- What went well?

- What did we screw up?

- What unexpected things threw us off course?

…is enough to get some good ideas. It is the principle of stopping and asking that we need to see more of. We don’t necessarily have to spend weeks investigating and probing in order to generate simple, effective and meaningful improvements.

Secondly, if you are stuck on the merry-go-round that is working life then you might just need to realise that it is up to you get off this thing. Accepting a little bit of short term pain in order to save hours each day / week / month going forward should be worth the hassle. You might even find that the hassle isn’t that great once you take a quick look.

I have seen many business transform their performance by asking a few basic questions, like the ones above, and then acting on the insights.

If you want to improve your on time delivery performance, or any other kind of business performance, then this approach is worth revisiting.