It’s true.

Many people chuck out good OTIF (On Time In Full) improvement opportunities too early. It can take time for an improvement to stick and effort to actually get a good result.

Does this sound familiar?

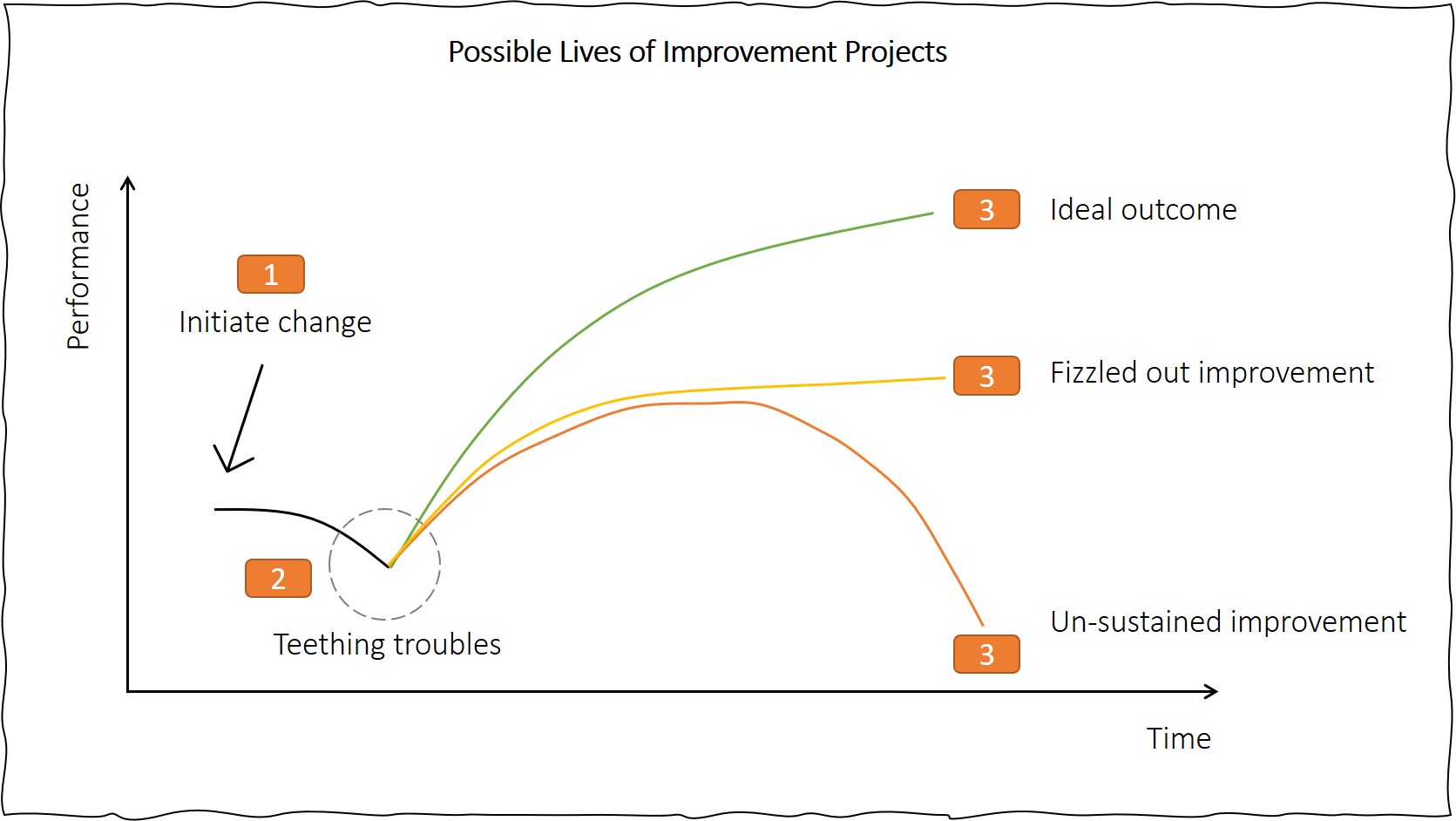

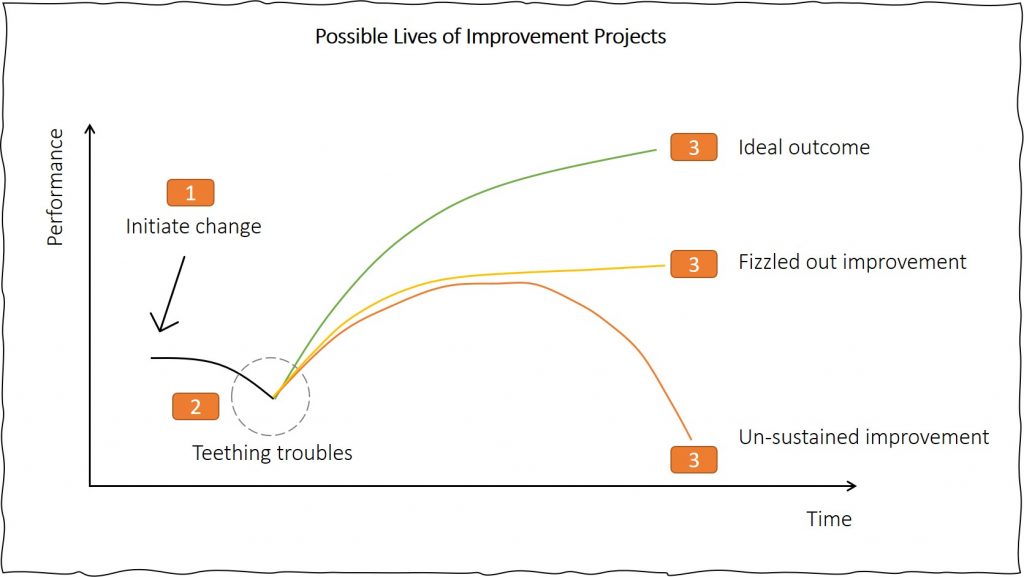

In this article I want to remind you about the ‘Y-Curve’ (also known as the change curve). My intention is to prompt some ideas that you have forgotten about. I want to encourage you to give them another whirl.

So, what OTIF improvements have you attempted recently?

How did they go?

Did they stick?

As I write this, I am reminded of a fabulous shop floor improvement that almost didn’t survive. A team of shop floor supervisors devised a communication tool to improve coordination. They wanted to improve the flow of information and production. The idea was a simple visual management tool. It looked like an effective solution.

When I returned a week later, the visual planning board was in the bin (literally!). The idea hadn’t worked straightaway and was therefore deemed a failure. It wasn’t a failure; the basic idea was sound. It was the implementation that had failed.

At the critical point…

At times like this, during an improvement phase, communication and instruction are key. This takes us back to the Y-Curve.

As you can see in the image below, performance often drops when you introduce a change. During this period, people need time to put a new idea into practice. You will need to clarify instructions. The resolution of new (unforeseen) problems has to take place.

They stuck with it!

That’s what happened with the shop floor team. We listed out the issues they had when using the new method. Over a period of weeks we ironed out the bugs. The system came to life and their on time delivery rates improved.

The alternative to persisting with an improvement is failure to change. This robs you of an improvement gain. This can demotivate your team and drain resources. Of course, you need to know when to cut your lossses too, but don’t be too hasty!

I had a similar experience, the other week, along these lines. My client realised that they needed to improve their holiday management system. Project delivery was being hampered by a lack of visibility of their staff’s leave. When they had ten team members it was easy. Now that they have more than fifty staff, things are a little more difficult.

They chose a software solution. We operated a pilot period and then rolled it out. We provided instructions and support. It worked well for the staff, but not for the people that needed the visibility… After listing out the concerns, we made small tweaks. It works well now and has helped them with their goal. We didn’t give up at the first hurdle.

Can you use Kaizen here?

Another strategy to consider here is Kaizen. You can apply this approach in two key ways.

- Breaking the improvement down into a series of smaller steps. This can eliminate the stress from the change. You deliver the improvement in a series of small steps.

- Separating the issues after you have launched the improvement. Tackling the issues one by one, in small bite size chunks, can also take the pressure off change. Correcting the improvement’s course is much easier this way.

Whatever way you use the Kaizen approach, nibble change fast!

Intent versus reality

The key message from this article is that practice and intent are not always the same on day one. To make a change happen you need to combine persistence with communication. Add in learning and rapid action and you have the recipe for successful change.

I hope that some of your past initiatives that didn’t quite make the grade come to mind. Take the points above and think about the way you roll out change. Can you can come up with a better way to make change happen, going forward? Are any of these past attempts worth revisiting?

Improving (delivery) performance can become clockwork, if you have the right approach.

Good luck with your next improvement. I’m sure it will be a success.