What happens when you miss your delivery schedules?

Do you do what the majority of businesses do and carry on with the next delivery (which is inevitably just around the corner) or do you change how you manage your business processes?

If the delivery failure is a blip then I’ll forgive you for not going into the depths of asking ‘why?’. But, if the delivery failure is part of the norm in the business then it might be time to look a little deeper.

Two types of businesses

I see two types of business based on the question above. There are those that believe that they will address their on time delivery issues by hard work and ‘graft’. On the other hand there are those businesses that don’t want to put up with the blood, sweat and tears approach. They want to find another way to manage their business so that delivering on time can be a more consistent and simpler affair.

Let me give you two examples of the blood, sweat and tears approach I have observed recently:

- A construction business was able to complete a large proportion of their production activities off site. Every time we spoke they seemed to be behind all of their internal markers regarding progress. However,they said that they would hit the installation dates and only be on site to complete the outstanding works for one week. As I write this we are entering week 5 (my client is their customer…). Instead of reacting to the failure in progress at the time it was observed they have pushed on. Most of their team are now on other projects and I doubt they will learn from this experience.

- A client, when I first met them, weren’t fit for their market. They did achieve a high level of on time delivery, but at the expense of the staff they kept on burning out. Their systems and processes didn’t help them. They relied on the sheer ‘grunt power’ of their team, which in most cases is a limited strategy. When you stood back from what was going on there were plenty of examples of wasted effort and illogical decisions. Thankfully this business wanted to do something different; every concern about how they delivered on time was an opportunity for improvement.

Embracing PDCA

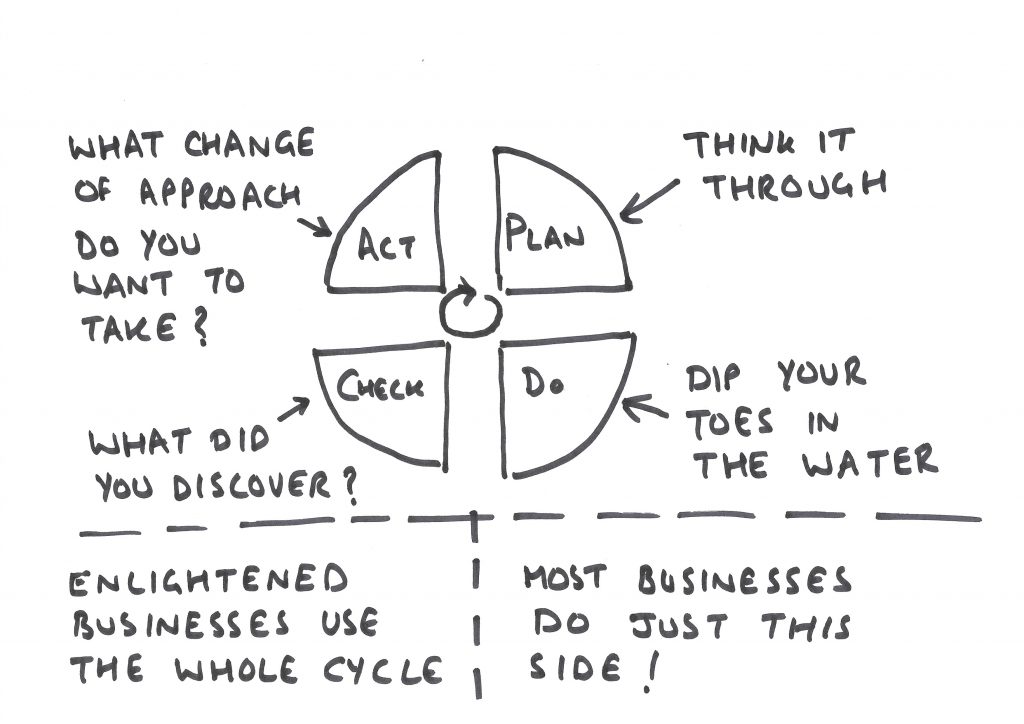

The standard remedy for this situation is to embrace the PDCA cycle. If you haven’t come across this acronym before it stands for:

Plan – Do – Check – Act

In essence this natural learning cycle requires that you:

- Plan out your tasks to achieve your objective.

- Do some of your tasks.

- Check how things are going and review your results to date.

- Act in a manner that will improve the results you are experiencing.

Checking early and frequently is a good place to start if you are struggling. Acting differently is essential for most of us whilst we figure out what works and what doesn’t.

The challenging question is why do most people / businesses do a bad job of this basic approach? It exists at the core of the main ISO system (9001, 14001 and 45001 for example), it is a tried and tested improvement framework.

Getting started

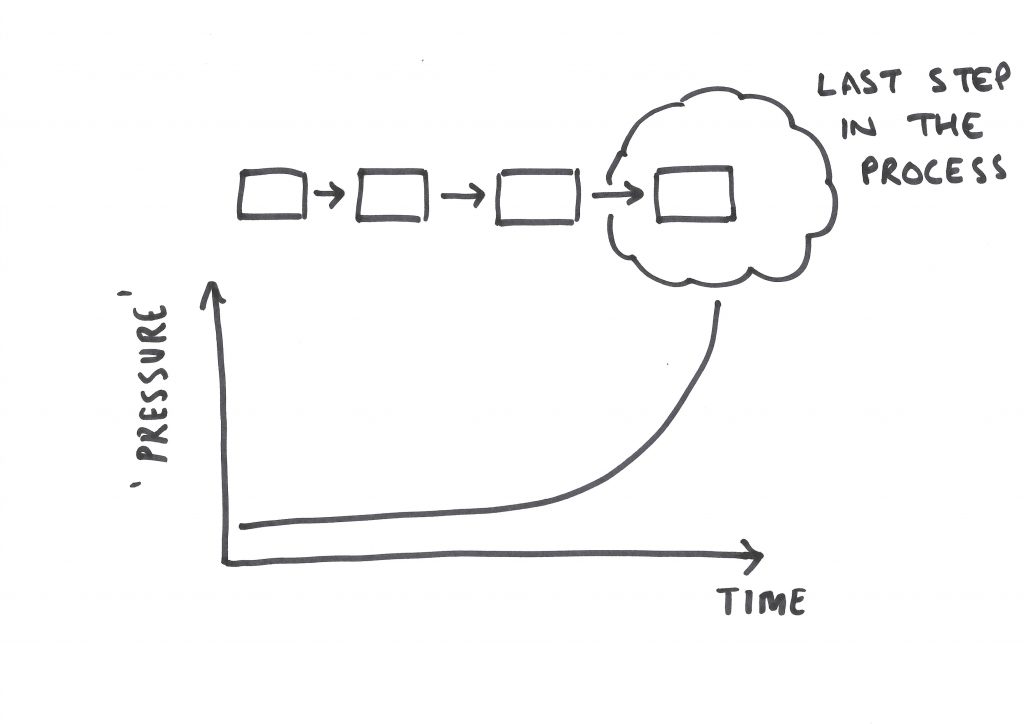

If you are unsure where to start, to apply PDCA, look at the last step in your product / service delivery process. Issues that aren’t effectively addressed by your business have a tendency to wash up at the final step in your process.

If you find that the business environment is generally cool and calm until the point where the products are despatched, or the service is delivered, then it is likely that there is some compensation activity going on. Things aren’t fine, the problems just aren’t visible earlier on.

Identifying these issues and applying PDCA to them, if nothing else, is a good place to start to use the power of feedback to improve your delivery processes.

Just start with something small

Small steps here shouldn’t be underestimated either. Improving the performance of your business, whether it is on time delivery or something else, doesn’t always have to be a huge overhaul. Let me give you two examples to reinforce this point:

- I used to be an Operations Manager at a factory that delivery (on average) 22% OTIF (On Time In Full). It was poor and the levels of phone calls I received from angry customers was way too high (I spent most of my days trying to fend off customers…). Once I had got my bearings it was a pretty straightforward improvement; sort out our capacity planning tools so that we could load the factory’s resource effectively. In short, this improvement took me a couple of afternoons to fix and allowed our OTIF score to hover in the 98%+ range within a couple of months. Our lead time also dropped and we tripled our turnover with no additional staff. None of this was rocket science but did require us to pay attention to the signs of failure that were all around us.

- One of my past clients were at risk of losing approximately 70% of their work volume due to poor delivery performance when I met them. By tweaking the logic of their ERP system and improving the communication between three departments this business graduated to the top of their supply chain league table. They won additional business from the same group of companies who that threatened to remove the work (another company in the same supply chain was also threatened, failed to improve and ultimately shut down the same year). The changes weren’t huge but the results were.

So, how effective is the feedback and improvement cycle in your business?

Could you take something small that is a symptom of your delivery woes and apply the PDCA approach to it?

If this article resonates with you, please don’t do the same thing tomorrow at work. Einstein was right about insanity; improving your on time delivery levels and reducing the hassle you experience won’t happen if you don’t change something.

Go and take a look at the last point in your delivery process and see what issues live there. Start your journey there; this doesn’t have to be complicated.

Giles